NEOL’s copper technology

Meet CuGlideTM – our ground-breaking copper filming technology, representing a fundamentally new approach to providing anti-wear, detergency and efficiency in technical lubricants.

Our scientists, who specialize in friction and wear, have developed CuGlideTM based on cutting-edge research into “hydrogen wear” and “the wearlessness effect.”

CuGlideTM technology | How it works

Hydrogen Wear

In the 1950s, engineers discovered that hydrogen was responsible for the majority of steel surface deterioration.

The Wearlessness Effect

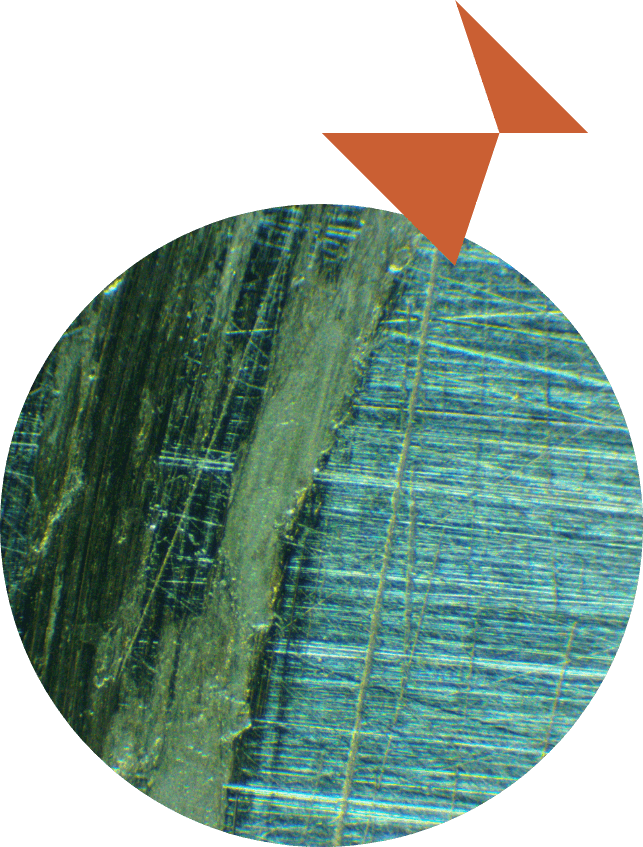

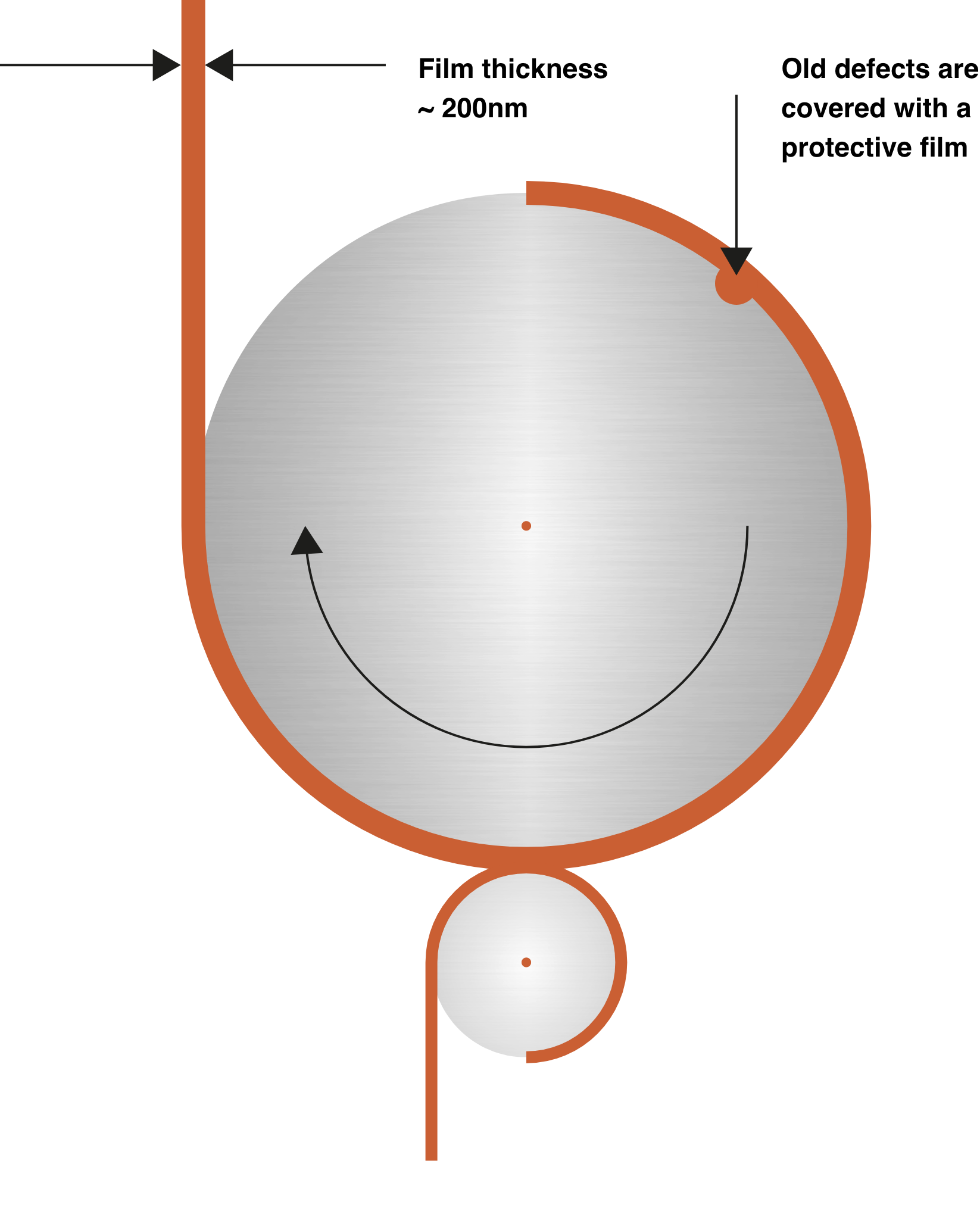

CuGlideTM technology takes advantage of the “hydrogen wear” mechanism. Rather than allowing uncontrolled hydrogen invasion of the friction surface, the additive technology first uses its properties to “polish” the friction surface at an elementary level.

The hydrogen wear is then terminated with copper ions.

- Hydrogen displaces steel molecules, accelerating the wear of machine parts.

- Copper ions are embedded in the crystal lattice of iron in iron-containing alloys, thereby “healing” damaged areas.

- They gradually form an even copper film covering an entire surface, at which point continued wear virtually ceases, “the wearlessness effect”.

The key to improved performance

With CuGlide technology, a copper film covers the machine parts’ surface, effectively “healing” any existing defects.

Additionally, as copper doesn’t react with hydrogen, the parts are protected against hydrogen wear.

As a result, friction is reduced, wear is eliminated, and the machine lifespan and operational performance increases.

NEOL research

Our CuGlide technology is built on groundbreaking research started by a group of engineering tribologists in the 1950s and continued to this day.

While there are four major known wear mechanisms that contribute to the damage and deterioration of machine parts: adhesive, abrasive, corrosive, and surface-fatigue, there is another wear mechanism that has gone largely underreported: hydrogen wear.

Studies have shown that it was hydrogen wear, not mechanical attrition, that was responsible for the majority of metal surface deterioration – as hydrogen displaces steel molecules, thereby accelerating the wear of machine parts. At least three of the four wear mechanisms mentioned above – adhesive, abrasive, and surface-fatigue – will contain the underlying effects of hydrogen wear whenever there is metal-to-metal contact with a temperature gradient, even on a micro level.

Our tribology experts have taken advantage of this discovery, using it to develop lubricants that control the hydrogen invasion of the friction surface.

The benefits of NEOL

Preserving the ecosystem through non-conventional composition

What sets NEOL apart is our commitment to safety and sustainability. Our proprietary additive package uses organic copper salts instead of toxic phosphorus and sulphur compounds. This unique composition doesn’t acidify and, therefore, doesn’t require a high base content or generate excessive amounts of sulphated ash. As a result, used NEOL oil is easily recyclable and, in some cases, fully biodegradable.

To find out more about the science behind NEOL’s CuGlide technology, or for further insight into its real-world applications, take a look at our videos below or follow the link to our YouTube channel to find out more.

If you still can’t find the answers you’re looking for, please don’t hesitate to get in touch